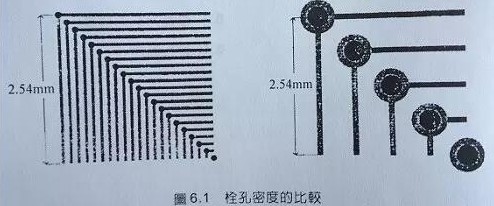

Figure 6.1 is a comparison of the 300-μm drilled hole hole in a typical FR4 circuit board and the 100-μm hole diameter in a PCB build-up circuit board. Since the signal lines are arranged in the X direction and the Y direction, a bolt hole must be arranged at the intersection of the X and Y directions of the wires so that the upper and lower layers can conduct. The bolt hole arrangement is arranged in a diagonal direction. This oblique line arrangement can achieve the maximum number of bolt holes. The density index of a typical high-density PCB board is expressed as the density of bolt holes. The number of pinholes that can be accommodated in an area per inch is expressed in VPSG units. In Figure 6.1, the FR4 board has a pin hole density of only 4 VPSG and the PCB build-up board has a pin hole density of up to 20 VPSG. In addition to the increase circuit board plane circuit density is 3 times the general FR4 printed circuit board, because the build-up circuit board insulation thickness is only 40um is also thinner than the FR4 circuit board, so the Z direction density is also FR4 circuit board is 2 times, Therefore, the circuit density of the entire build-up circuit board can be more than 10 times that of the general FR4 circuit board. Because the circuit density of the build-up circuit board is much higher than that of the FR4 printed circuit board, the production yield of the build-up circuit board can be greatly reduced if the precision required for the process cannot be ensured.

Check the PCB build-up circuit board

The glass fiber substrate of a conventional FR4 printed circuit board is formed by laminating a glass fiber cloth containing epoxy resin and a copper foil, and then mechanically drilling to form a through hole between the upper and lower layers, and forming it by photo-etching. line. Therefore, part of the process is machining, and part of it is chemical process.

In addition to the small part of the perforation process, the PCB build-up circuit board is basically completed by a chemical process. Due to the fact that the line density is much higher than that of traditional FR4 circuit boards, quality control is performed. It is very important for the build-up circuit board to control the process error. Therefore, how to select the process control parameters and control process parameters is a very important task. However, because many process parameters cannot be directly inspected or observed directly, how to monitor these process parameters is one of the key factors in determining whether or not the mass-produced circuit board production technology is mature.

Contact: Lillian Zhu

Phone: 008613928048496

Tel: 0755-28628518

Email: leappcb@163.com,sales@leappcb.com

Add: Hongtian industry,baoan area,shenzhen city,guangdong ,china