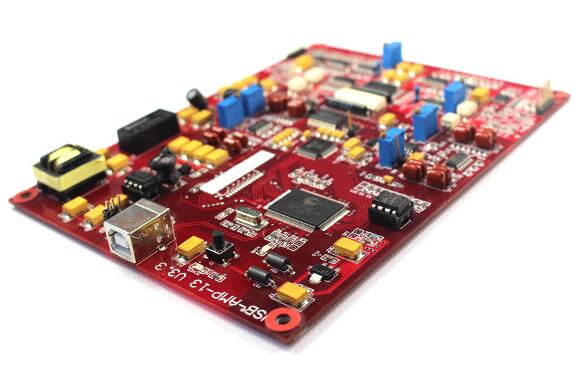

1. Check whether all the components on the board are consistent with the BOM. There are no adverse conditions such as low material or wrong components.

2, the polarity of the tiling element is correct.

3, the appearance of components is complete,without damage, battery insulation can not be damaged, dirty, painted.

4, check whether the solder joints tip, false welding, false welding, trachoma, warping, short circuit, welding, solder and other bad situation.

5, IC, PCB, triode, BGA, QFN need to check the material screen printing is correct.

6. All DIP components need to be 100% tin-through, and the front pad tin solder needs to wrap the leads.

7, the pcba board components can not set monuments, can not be offset.

Contact: Lillian Zhu

Phone: 008613928048496

Tel: 0755-28628518

Email: leappcb@163.com,sales@leappcb.com

Add: Hongtian industry,baoan area,shenzhen city,guangdong ,china