With the development of electronic products in recent years, the functions of automobiles have also gradually increased. Vehicle-mounted chargers, vehicle-mounted cigarette lighters and other auxiliary function devices have appeared one after another. As a result, the use of car-filled PCBA boards has gradually increased. Then, PCBA boards are selected. How should we ensure the quality of use? The following small series for everyone to share high-quality PCBA board should meet what requirements.

First, from the design and performance can be judged by the following points;

1. After installation, the connection performance is good within the required test range. For example, the input voltage, output voltage, current, temperature, class brightness, load power, etc. that need to be detected after installation.

Second, we can distinguish the circuit board through four aspects to analyze if this board is good or bad;

1, the size and thickness of the circuit board.

The edges of the board should be smooth without burrs. The shape is not deformed so as to avoid deformation of the outer shell after installation, and the screw holes are misaligned. It is now a mechanical installation. The hole position of the circuit board and the deformation error of the circuit and design should be within the allowable range.

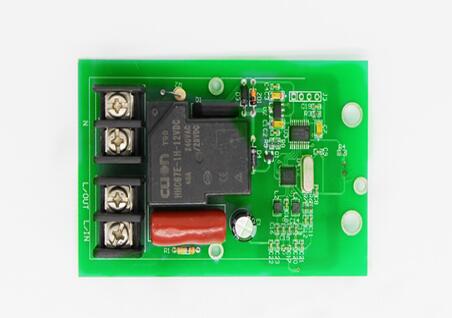

2, the circuit board ink and color.

The surface of the circuit board is covered with ink, and the ink can play the role of insulation. If the color of the board is different or the thickness of the ink is not uniform, the electrical function of the circuit board may be affected.

3, visual inspection line appearance.

Whether the design line structure is smooth or not. (Some lines have design flaws and no path will require additional wiring to achieve such functions as PCBA. Although electrical inspection can pass but affect appearance)

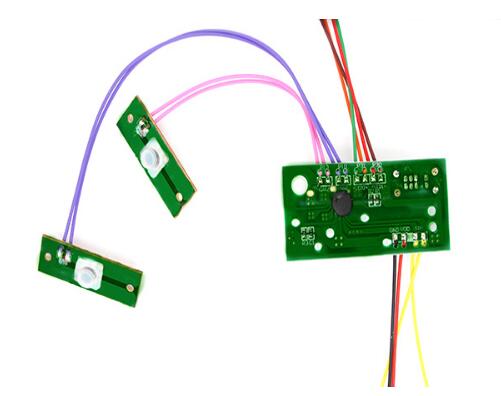

4, SMD and welding appearance.

It is required that the surface of the circuit board is clean and the position of the parts is within the pad position. Patch size and post-welding parts material batch size uniform, no floating high false welding false solder welding

Contact: Lillian Zhu

Phone: 008613928048496

Tel: 0755-28628518

Email: leappcb@163.com,sales@leappcb.com

Add: Hongtian industry,baoan area,shenzhen city,guangdong ,china