What is the "burn" program in PCBA

In the

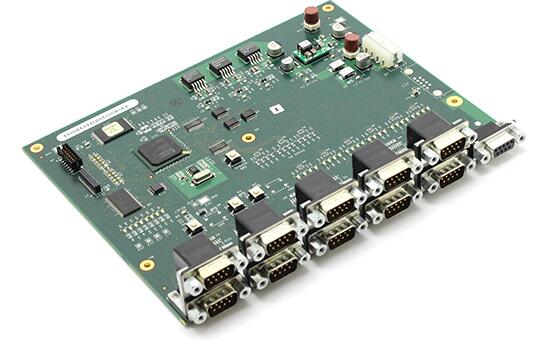

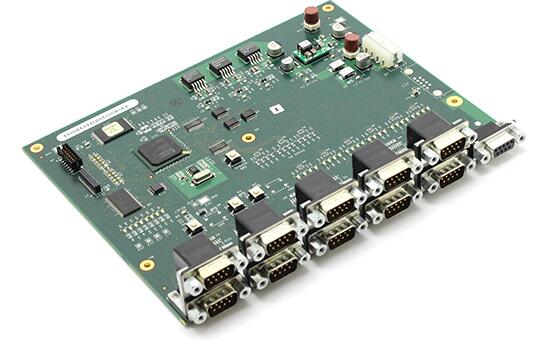

PCBA processing process, in order to allow the PCB board to achieve certain specific functions, in addition to the hardware is no problem, but also need to add software functions to be able to, at this time, we need to carry out the program "burning" at the beginning " Before burning, we have to test whether the PCB board is qualified and then select the appropriate burning method.

The current burning methods are generally divided into offline burning and online burning.

Off-line burning: Through the adapter and different packaged chip links, the chip and the adapter can be used together to achieve the programming. The nature of the adapter is similar to that of a precision fixture. Different packaged chips need to be fitted with different adapters. If an error occurs in the production test and the production is retrospectively revised, it is necessary to remove the chip from the adapter and re-program it in accordance with the prescribed procedure. It takes a lot of manpower and material resources, the cost is high, and it is also more prone to problems. Therefore, offline programming is not generally recommended.

Online burning: Online burning uses the standard communication bus of the chip, such as USB, SWD, JTAG, UART, etc. The interface is generally fixed, and the pins required for connection during programming are also very few. Because the communication speed of the interface is not high, the general wire can be used to complete the recording without high consumption. Online programming is performed by programming the connection through the wire connection. If an error is found during the production test, reprogramming is possible without disassembling the chip. Not only saves production costs, but also increases the efficiency of burning. So now we generally use online burning methods.